Process Solids Separators

Mechanical separation made easy

Norchem’s offers various suspended solids removal technologies to remove diverse solids from the waste stream. We offer vibrating screens, self-cleaning trench screens, rigid basket filters and vertical bowl centrifuges.

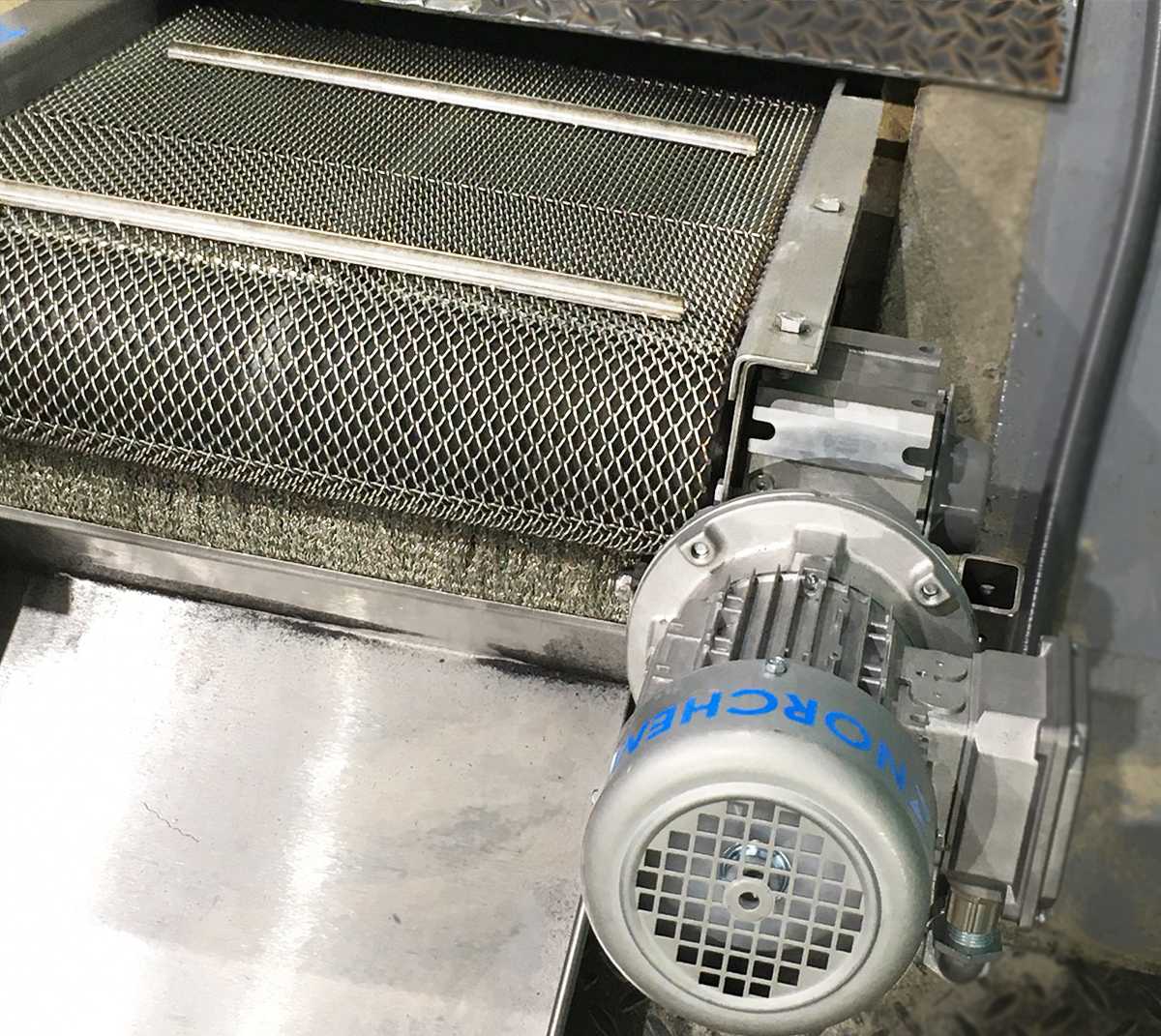

trenchmaster

A stainless-steel conveyor screening system to remove large solids in the wastewater prior to the clarifier or wastewater pit.

Technical Features

Shaker Screening Systems

Norchem’s shaker screening systems remove lint and large particles to lower TSS prior to discharge to the city, and prior to ultra-filtration or wastewater heat exchangers.

Excellent for companies looking to accomplish passive water reuse or who are trying to comply with discharge regulations, if there is a TSS limit at the sewer.

technical features

UltraSep™ Centrifugal Solids Separator

Solids Removal with Force

The UltraSep™ Solids Removal System is the superior solution for removing sand, silica, gravel, and other particles from wastewater streams. Excellent option for operations with tight TSS discharges requirements.

technical features