Plant Data Systems

measure. analyze. optimize.

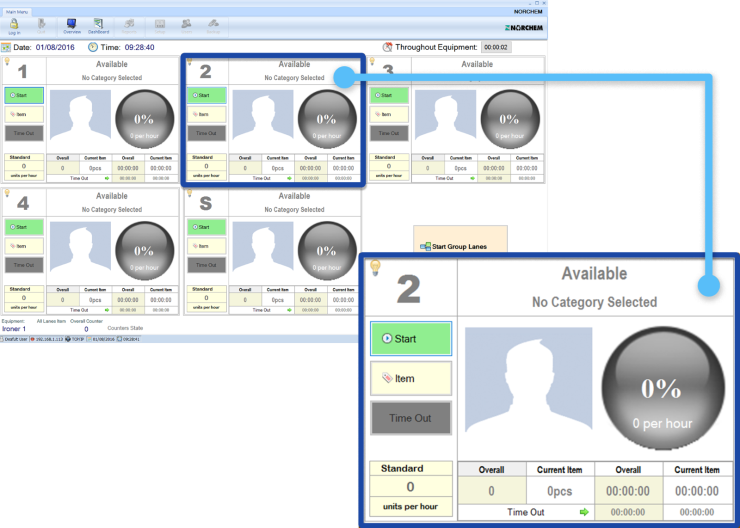

Developed to provide a full-featured production and utility information management system to capture data, analyze it, and report it through an interactive dashboard. NorVision™ answers the tough questions in detail about production levels down to the individual plant worker on the plant room floor.

NorVision™ Plant Data Systems

Managing complex laundry operations without data is an intimidating task. Transform your uncertainty into opportunity by improving laundry efficiency in three steps: Measure, Analyze, and Optimize.

Utilities like water, pressure, and energy usage are tracked and reported via the dashboard in a way your management team can understand.

TECHNICAL FEATURES

- Comprehensive Production labor management system, using real-time worker efficiency data to optimize workflow & increase productivity

- Overhead displays show employee productivity percentages using bold graphics

- Collects real-time production information at each workstation and measures output & reports data by employee, item type, and machine allowing you to track data to improve day-to-day performance

- Accessible remotely, the system is scalable and can be applied to your entire workforce or to various sub-groups

technical features

- Gas consumption while monitoring efficiency of dryers, boilers, water heaters, and steam tunnels

- Water consumption monitoring for wash floor, boiler feed water, softener regeneration water, hot water and tempered water

- Temperature monitoring for hot water, tempered water, water heaters, and heat reclaimers