Division Breakdown | Sustainable Water Systems

April 21, 2022

"Our divisions were created as the Norchem team continued to pursue solutions for challenging environments. With each successful solution, came a new product offering. Over time, our product offerings eventually spanned 4 divisions."

- Vaughn Minissian, Norchem President

Division Breakdown | Sustainable Water Systems

Norchem is the most inventive and trusted filtration and reuse water technology source for commercial and industrial applications since 1990. From commercial laundries to food processing plants, our engineering team is responsible for treating billions of gallons in process water and keeping facilities in compliance under the most stringent discharge limitations set by POTW’s.

Norchem Water Systems are engineered with a focus in improving our customer’s bottom line through the conservation of our most precious resources: water and energy.

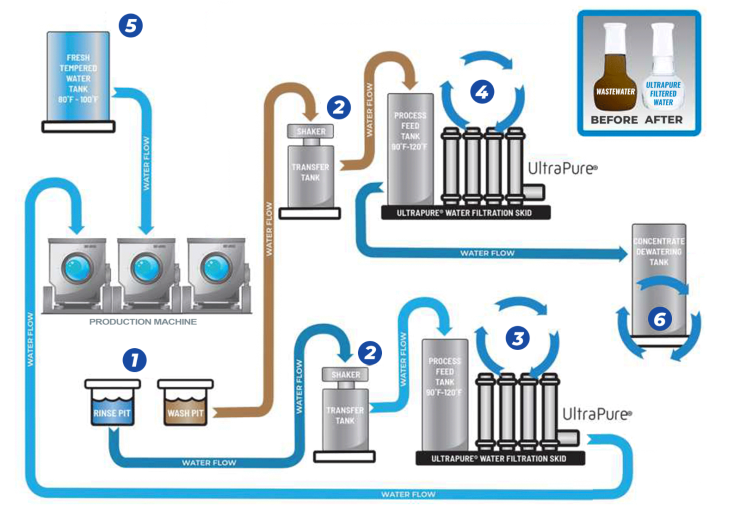

Our Sustainable Water Systems division includes products such as The UltraPure®, the RO Pure™, Ultrasep™, Water Softener, Hot and Tempered Water System, Heat Exchangers and even treatment chemicals.

Norchem's Wastewater Reclamation Systems

Norchem’s water technology division brings more than 30 years of innovation to smart water reclamation technology. Straight from our Skunk Works project team in Los Angeles, CA, Norchem developed one of the first “best in breed” Ceramic Membrane Filtration (CMF) and Reclamation Systems for industrial effluent waste streams in processing plants since 1995.

Named Ultrapure as a nod to its Ultrafiltration capabilities, the UltraPure system produces high quality recycled water for applications in commercial laundry, food processing, and many others, with no added treatment chemicals. The ultra-filtration process uses an innovative ceramic crossflow membrane design that can reclaim up to 85% of wastewater and wastewater heat. It is designed to fit in any plant, big or small, with added capacity for future growth at less cost.

The Ultrapure system is proven to substantially reduce wastewater discharge by as much as 85% in most industrial applications where water can be reclaimed. This system also minimizes Delta-T by up to 85%, eliminating the need for additional expense on water heating equipment.

Norchem's Reverse Osmosis Systems

Total Dissolved Solids (TDS) reduction is a critical area focused on by plant engineers who seek to improve process water quality for production plants. No matter if it is process water, brackish water, sea water, or wastewater, we offer a sustainable cost-effective solution for purification.

Norchem’s Reverse Osmosis System, RO Pure™ is used for incoming water filtration and process water tertiary filtration to remove TDS. It uses membranes with specialized coating to increase the flux rate by as much as 70%. If your plant uses water in its production process and requires low TDS process water, then ROpure™ is a worthwhile solution to explore. This system is designed for scalability and flexibility, and removes dissolved solids in the water, such as sodium chloride, calcium, iron, silica, manganese, PFAS compounds, amongst others.

Some typical applications of the ROpure™ system are incoming laundry water. In addition to hard water, high TDS is known to cause problems with linen discoloration. Using ROpure™ in your wash process mitigates the risks of hard water that result in spending more money on excess wash chemicals and elongated wash times. Using the system for boiler feedwater filtration increases the cycle time of boilers, and results in improved efficiency and lifespan of boilers.

From our state-of-the-art Wastewater Filtration and Reclamation Systems to our Wastewater Heat Recovery Systems, we guarantee a competitive advantage to our customer’s by abating their carbon footprint, and slashing their utility bills.

READ MORE on the rest of our Sustainable Water System offerings by visiting our Products pages.